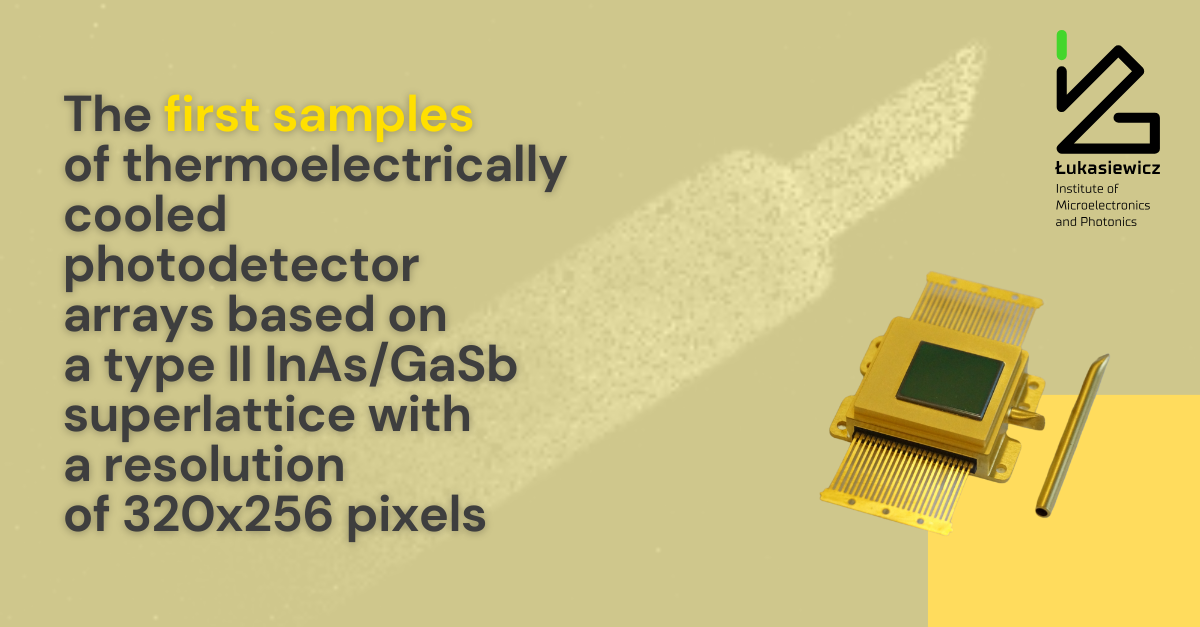

We have produced the first samples of thermoelectrically-cooled Focal Plane Arrays (FPA) based on type-II InAs/GaSb superlattices with a resolution of 320×256 pixels. The imaging capability of the initial FPA was confirmed by our researchers on October 26, 2023. This achievement is part of an ongoing project titled “Development and Implementation of the First Polish Camera Based on Uncooled Photodetector Arrays of Type II InAs/GaSb Superlattices operating in the 3 μm to 5 μm band,” led by Agata Jasik, PhD, DSc, and funded by NCBR.

All stages of production, except for the underfilling and welding of the FPA package components have been carried out at Łukasiewicz – IMiF. The photodetector heterostructure based on the type II InAs/GaSb superlattices has also been manufactured at our Institute.

Our matrices adhere to the SWaP-C (Size, Weight, Power, and Cost) criterion. Instead of heavy cryocoolers weighing several hundred grams, we use Thermoelectric Coolers (TEC) that weigh just up to a few grams. TECs have a long lifespan, MTTF > 100,000 hours, while the lifespan of cryogenic refrigerators is limited, MTTF < 30,000 hours due to the finite cycles of gas compression/expansion. Additionally, TEC coolers feature a shorter cooling time needed for achieving the operating temperature.

Now, let’s move on to some project statistics:

- 12 specialists from Łukasiewicz – IMIF were involved in the FPA production.

- A total of 34 technological steps were carried out during the FPA manufacturing cycle.

- In the near future, the FPAs produced at Łukasiewicz – IMIF will be used in constructing cameras operating in the mid-infrared spectral range (from 3 to 5 μm). In this phase, we collaborate with CRW Telesystem Mesko Sp. z o.o.

FPAs find applications in both civilian and military sectors.

Common civilian uses include gas leak detection, non-invasive inspection of electronic circuits, medical imaging and thermography. In the military segment, the cameras can be employed in missile guidance systems, targeting, and battlefield surveillance.

The global optoelectronic industry is constantly working on improving the quality of FPA production technology. The goal is to achieve such figures of merit, which will eliminate the need for cryogenic cooling. In Poland, Vigo is engaged in the development of infrared FPAs, while worldwide, companies like IRnova AB and Lynred are active in this domain.

Although infrared cameras are not new on the market, what makes us distinctive is the thermoelectrically cooled FPA. Polish manufacturers offering such cameras primarily use Microbolometer or HgCdTe-based FPAs imported from abroad, depending on the spectral range. Now, they may be interested to know that we may have an alternative, and perhaps a better solution for certain applications right here in Poland!