Financing:

Project acronym: POLONEZ BIS 1 “BAGBONE”

The main goal of the project is to verify if bioactive glass wool based on microfibers can be accommodated into bone defects, easily matching their shapes and transform into hydroxyapatite, finally forming a bone tissue similar to natural one.

Description

Bone is the second most transplanted tissue worldwide, right after blood transfusions. Bioactive glasses, which are nowadays available commercially and considered for bone regeneration, suffer from poor thermal stability, inappropriate dissolution rates, which do not suit the time needed for the regeneration of bones. Alkali-free bioactive glasses may be considered as good candidates to solve all the challenges mentioned above. They have moderate dissolution rates better adjusted to the bone regeneration process, broader thermal stability windows than 45S5 glass, they are not cytotoxic and they are characterized by fast formation of a HCA surface layer, which supports strong bonding to the bone and soft tissues.

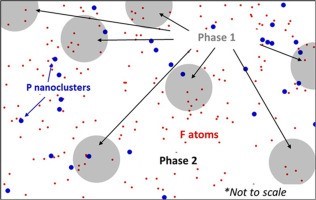

The main goal of the project is to verify if bioactive glass wool based on microfibers can be accommodated into bone defects, easily matching their shapes and transform into hydroxyapatite, finally forming a bone tissue similar to natural one. An alkali-free bioactive glass based on Diopside (Di) – Fluorapatite (FA) – Tricalcium Phosphate (TCP) system will be used as parent glass and will be doped with suitable amounts of oxides of B, Na, K, Sr, Zn and Zr. We aim to modify a glass composition to enhanced thermal stability and avoid low liquid-liquid phase separation which is crucial to enhance the glass stability, as the low-temperature glassy phase may crystallize under the glass fibre drawing processing conditions. This strategy involves the incorporation of therapeutic ions that will be leached off and delivered after implantation to stimulate bone regeneration, therefore further enhancing the biological performance of the bioactive glass.

Next, we plan to develop bioactive glass microfibers using Saint Gobain method and form glass wool dedicated to fill bone defects and regeneration of the bone. For this purpose, we will establish a dedicated system for microfiber development in laboratory scale. We target a development of glass wool in volume of a few cm3 in one run composed microfibers with diameters of 10-20 μm and lengths of 1 -5 mm. The size of individual microfibers will be adjusted dynamically with operation parameters of the developed equipment. We also aim at a comprehensive in-vitro assessment of the biological performance and bone regeneration ability of the bioactive glass wool constructs. They will include but not limited to: degradation (according to ISO 10993-14), ion-release, bio-mineralization (according to ISO 23317), complex cell culture tests under both static (according to ISO 10993-5) and dynamic conditions. The biomineralization capacity of the bioactive glass fibres (i.e., ability to generate the formation of carbonated hydroxyapatite-like layers on their surface in contact with synthetic intercellular media) will be carried out by immersion in both the Kokubo’s simulated body fluid and the complete cell culture medium, in homeostatic conditions. After each experiment, the samples will be separated by filtering, and the apatite-forming ability of the dried glass wool samples will be inferred by morpho-compositional (surface and cross-sectional SEM-EDX) and structural (FTIR spectroscopy and XRD) analyses. Selected samples, with promising biomineralization responses, will be further subjected to adhesion, viability/proliferation and differentiation screening assays.

Finally, the in-vitro bone regeneration process will be verified experimentally (having as makers both biomineralization and cell behaviour) in the perfusion bioreactor. The process of hydroxyapatite formation and its transformation into bone-like tissues will be continuously monitored with custom made imaging system based on dedicated imaging fibres. A bioreactor provides a dynamic culture system for efficient exchange of nutrients and mechanical stimulus. These experiments will be performed using hMSC seeded onto porous bioactive glass wool scaffolds incubated in a humidified atmosphere at 37 ºC and 5% CO2, according to specific ethical and experimental protocols.

Principal Investigator:

Dr Jose Maria

Da Fonte Ferreira

Funding

This research is part of the project No. 2021/43/P/ST7/02418 co-funded by the National Science Centre and the European Union’s Horizon 2020 research and innovation programme under the Marie Skłodowska-Curie grant agreement No 945339.

Project location

Photonic Materials Research Group

The research activities of Photonic Materials Research Group include the development and characterization of special optical fibers, micro-optical components, transparent and bioactive ceramics and special glasses. The area of application and practical use of developed components comprisesmicro-fluidic systems for sensing or biomedicine, all-fiber systems for lasing, beam delivery or telecomunications, biocompatible ceramics for medical treatment.

Research Group Leader: Prof. dr hab. inż. Ryszard Buczyński, ryszard.buczynski@imif.lukasiewicz.gov.pl

Project news

December 2024

Zapraszamy na seminarium Prof. J.M.F. Ferreiry

Zakład Fotoniki Uniwersytetu Warszawskiego Wydziału Fizyki zaprasza na Seminarium pt. czytaj więcej...

May 2024

Professor Ferreira gave a lecture during 9th International Workshop of Materials Physics in Măgurele, Romania!

Professor José M.F. Ferreira, was invited as a guest to czytaj więcej...

October 2023

BIOCERAMICS 33 conference talk!

Prof. Ferreira attended the Bioceramics 33 Conference held in Solothurn, czytaj więcej...

Cotton-like glass fibres, bone defect, and 3D-printing – an interview with J.M.F. Ferreira

During our discussion with José Maria De Fonte Ferreira from czytaj więcej...

June 2023

New Article published in Elseviere’s Acta Materialia !

New Article published in Elseviere’s Acta Materialia ! We are czytaj więcej...

December 2022

POLONEZ BIS Programme Kick-off meeting!

BAGBONE PI - Professor José Maria da Fonte Ferreira participated czytaj więcej...

Contact details

Dr Jose Maria Da Fonte Ferreira

Principal Investigator

jose.ferreira@imif.lukasiewicz.gov.pl

Project Researcher

Mgr inż. Przemysław Gołębiewski

przemyslaw.golebiewski@imif.lukasiewicz.gov.pl

Project Administrative Assistant

Mgr Anna Jagiełło-Bosiek

anna.jagiello.bosiek@imif.lukasiewicz.gov.pl